Under the general term “aramid,” the US Federal Trade Commission adopted the following designation in 1974 to characterize fibers based on aromatic polyamides: “a manufactured fiber in which the fiber-forming substance is a long chain synthetic polyamide in which at least 85% of the amide (—CO—NH—) linkages are attached directly to two aromatic rings.” The general reaction that occurs between an amine group and a carboxylic acid halide group produces aramids.

In the 1960s, aromatic polyamides made significant strides in the commercial arena when DuPont introduced the meta-aramid fiber Nomex, expanding the possibilities for thermal and electrical insulation. Monsanto created an aromatic co-polyamide fiber, codename X500, in the 1970s based on an aromatic polyamide–hydrazine combination that almost made it to market. In 1971, DuPont developed and brought to market a fiber with much greater modulus and tenacity, which it marketed under the brand name Kevlar. At the close of the 1980s, Twaron, an aromatic co-polyamide and another para-aramid akin to Kevlar (Twaron is a registered product of Teijin), hit the market. Teijin commercialized the Technora (a registered product of Teijin) fiber after an impressive scientific interpretation of the previous art by Ozawa and Matsuda, who were pioneers in the creation of the aromatic co-polyamide fiber.

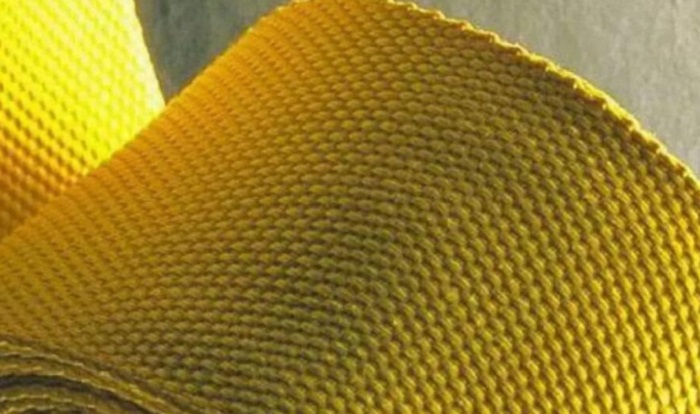

This section delves deeply into the realm of aramid compounds that are sold commercially. MPDI (poly-(m-phenylene isophthalamide)), PPTA (poly(p-phenylene terephthalamide)), and ODA-PPTA (co-poly(p-phenylene-3,4-diphenyl ether terephthalamide)) are the three primary forms that are discussed. Nomex (DuPont) is the most widely used brand for MPDI fibers, while Kevlar (DuPont) is the best brand for PPTA fibers. Teijin also sells Technora, an ODA-PPTA copolymer, and Twaron, a PPTA-based product. It’s interesting to note that Twaron and Kevlar have the same chemical composition (PPTA). Because aramids have high melting temperatures, the conventional process for generating aliphatic polyamides is not appropriate for them. Thus, to create PPTA molecules from 1,4-phenylenediamine (PPD) and terephthaloyl dichloride (TDC) monomers, a unique procedure using NMP (N-methyl-pyrrolidone) and CaCl2 (calcium chloride) solvents is needed. Three steps are involved in the manufacture of aramid: polymerization, spinning of filament yarn, and conversion into pulp, short-cut, or staple fiber forms. Using a low-temperature polycondensation method with m-phenylenediamine and isophthaloyl chloride in an amide solvent, MPDI aramids are easier to make. Both dry and wet spinning techniques may be used to spin these fibers. The polymer solution enters a coagulating bath via microscopic pores in wet spinning, where it undergoes stretching, washing, and drying processes. Lastly, Teijin’s co-polymer aramid, Technora, combines three monomers: 3,4-diaminodiphenyl ether, p-phenylenediamine (PDA), and terephthalic acid. By adding flexibility to the backbone chain, this ether monomer produces a fiber that has marginally superior compression capabilities than PPTA aramid fibers made by the liquid crystal process. In this method, an amide solvent containing a tiny quantity of lithium chloride or calcium chloride is utilized.

Formation of Aramid Fiber: A Twist during Wet Spinning

Aramids use a dry-jet wet-spinning method, which is a novel approach to fiber creation. There are major differences between this technology and the conventional wet-spinning procedure. The fiber-producing nozzle in a typical wet spin process plunges straight into a coagulating liquid. On the other hand, dry-jet wet-spinning employs another method. A spinneret placed directly above the coagulating bath—typically water or diluted sulfuric acid—is used to extrude the aramid solution. Before the solution begins to harden, this air gap permits the polymer chains inside it to align even further. The air gap and the particular spinneret capillary design combine to cause the polymer domains to rotate and align. As-spun fibers that are extremely crystalline and aligned from the beginning are the outcome of this. Arimids’ exceptional strength and modulus (stiffness) are due to the liquid crystals that are present in their solutions and their anisotropy (directional dependency). The extraordinarily high degree of orientation and connection between the polymer molecules is a result of these variables. Aramid has remarkable qualities that may be best described as long, strong chains that are precisely arranged and securely bonded.

What makes Aramid Fiber what it is? The very stiff building units of Poly(p-phenylene terephthalamide), also known as PPTA, are responsible for the material’s extraordinary strength. To maximize their stability, these rigid “phenylene rings” are connected in a certain “para” orientation. The amide groups that are positioned throughout the lengthy backbone of PPTA like beads provide another significant benefit. These amide groups have the strong “hydrogen bonding” effect that draws nearby PPTA chains to them like little magnets. A super-stable network is created by the considerable sideways bonding between chains, which greatly enhances the strength of the material. Remember that comparable materials referred to as “meta-aramids” fall short of PPTA in terms of strength. This is because they are more flexible, like textile fibers, due to the way their chains are joined (in a “meta” orientation). Although they may not be the strongest, meta-aramids have good thermal stability, which makes them useful for a variety of applications.

Aramid Fibers’ Chemical Properties: The “amide link” is the common thread that binds all amides together. This unique bond is hydrophilic, meaning it likes water, but how much moisture it absorbs depends on the particular aramid. For instance, PPD-T (poly-phenylene terephthalamide) fibers excel in withstanding a wide range of harsh substances, including salts and organic solvents. Strong acids, on the other hand, may be their kryptonite and severely reduce their potency. The process of dying aramids may sometimes be challenging. When it comes to absorbing color, their high “Tg” (glass transition temperature) makes them obstinate. Another fascinating feature is that when para-aramids are exposed to UV light, their aromatic structure allows them to react with oxygen. Unfortunately, this may result in a change in color and a reduction in their strength.

The Thermal Resilience of Aramid: Aramids don’t melt in the conventional sense, unlike other materials. Rather, they break down at very high temperatures. It’s also difficult to light them on fire because of their low “oxygen index values.”It’s amazing to know that certain aramid varieties can withstand temperatures as high as 300 degrees Celsius and yet maintain around 50% of their strength. They also have a high degree of crystallinity, which implies that even at high temperatures, they seldom shrink. They are thus perfect for uses where it’s essential for the object to retain its form at high temperatures.

Aramid yarn’s mechanical property is its powerful punch! It has a strength more than five times that of steel underwater, with a breaking tenacity of 3045 MPa (and four times stronger even when dry). That is two times as strong as nylon or glass fiber! Its highly organized crystalline arrangement and the aromatic and amide groups within its structure combine to give it an amazing level of durability. The incredible thing is that aramid can withstand temperatures as high as 300 degrees Celsius without losing its strength or elasticity (modulus). Envision being supple and powerful despite the intense heat! Aramid responds to strain in a predictable way, extending like a spring within a certain range. It does, however, display a non-linear plastic deformation at extreme bends, which means it may adopt a persistent bent instead of precisely springing back. Still, that’s not all! Aramid is an endurance champion. Even under exceptionally high loads and long cycles, it exhibits no symptoms of breakdown under repetitive stress (tension fatigue). How incredible is that endurance! Furthermore, aramid has very little creep strain—just 0.3%—which means that it can withstand deformation over time even under continuous pressure. Because of this, it’s perfect for applications that need constant steadiness.

Aramid fibers have found their way into a variety of applications due to their exceptional strength and heat resistance. They are utilized in the aviation sector for parachutes and aircraft panels, among other things. They are perfect for all kinds of ropes and cables, from tiny wires in electrical gadgets to mooring lines for large ships, thanks to their remarkable strength. Aramid fibers are even used in construction, where they are used to sustain bridges and reinforce concrete. They are used in the automobile sector for tires and vehicle components, and their toughness is advantageous for recreational items like skis and hockey sticks. The special qualities of aramid fibers are used in daily products like conveyor belts and fireproof clothes, as well as in medical applications.