A broad variety of technologies dealing with structures and processes at the nanoscale are collectively referred to as nanotechnology. Nanotechnology is considered a vital technology that will not only affect technical growth in the near future but also have economic, social, and ecological ramifications because of its ability to profoundly alter whole sectors of technology.

Approximately 1 to 100 nanometers (1 billion nanometers = 1 meter) are the dimensions that nanotechnology works with, while 100 nanometers is now the realistically achievable range for textile goods and applications.

The method may be utilized to generate enhanced performance qualities in fibers, yarns, and textiles, such as water repellency, fire retardancy, and antimicrobial resistance, as well as desirable textile features including fabric softness, durability, and breathability.

With enormous scientific, economic, and ecological advantages, the enhancement of textile materials by nanotechnology is predicted to become a trillion dollar industry in the next ten years. According to estimates, in addition to the millions of dollars contributed by the private sector, global government support for nanotechnology research and development reached $3 billion yearly in 2003.

The fiber and textile industries were really the first to effectively integrate these advancements and show the uses of nanotechnology for consumer consumption, despite the textile industry’s minor share of worldwide research in the developing fields of nanotechnology.

The field of textile finishing has expanded with the introduction of nanotechnology. One method for creating highly active surfaces with UV-blocking, antimicrobial, and self-cleaning qualities is to nan coat the surface of textiles, apparel, and textiles for footwear. Nano-TiO2/nano-ZnO coating is one way to impart the self-cleaning capability.

Textiles have evolved from practical to clever and sophisticated

Items of clothes, accessories, and footwear with microelectronic sensors are referred to as intelligent clothing. The fusion of stylish and intelligent apparel is known as smart clothes. The level of physical activity and the ambient temperature determine how much thermal insulation is needed in garment systems. The amount of heat the body produces varies greatly depending on the activity level; it may range from 100 W at rest to over 1,000 W at maximal effort. The required thermal insulation is established in order to guarantee that the body is adequately heated when at rest during the colder months, around 0 C.

When engaging in a more strenuous exercise, like athletes do, the body produces more heat, raising body temperature. The body perspires to remove energy from the body via evaporative cooling in order to maintain this rise within a particular bound. Phase shift and shape memory textiles are two examples of intelligent textiles that are used to increase insulation. The fashion industry is another major use for intelligent materials, as chromic materials are used to produce fantastical designs. These include, for instance, work suits, solar-rechargeable coats, music-themed t-shirts, and more. The fashion industry is entering a whole new era with the incorporation of electrical technology into garments.

The functional materials that are now available on the market have high breathability, are windproof, and can transfer moisture. They have optimal material qualities, such as resistance to heat and cold, color fastness, tearing and rubbing strength, etc. Odor release or prevention, phase change materials and microcapsules, individually adjustable thermal insulation, and defense against environmental stressors like UV radiation are among the new products available on the market. Nanotechnology is already having an effect on the textile sector. The utilization of materials with nanoscale sizes and the creation of nanostructures throughout the manufacturing and finishing processes are the primary goals of these research projects.

Using nanofibers in nonwoven web applications

When compared to commercial textiles, nonwoven materials made of nanofibers have a larger specific surface area and smaller pores, which makes them great options for filter and membrane applications. Even though the process of electrospinning creates nonwoven fiber mesh, which is inherently disordered, mesh with different levels of fiber alignment may be created. In the future, it is anticipated that eco-friendly methods would be used for the mass manufacturing of fibers due to the electro-spinning process’s adaptability and versatility.

This century will see significant advancements in nanofiber applications and process optimization, with electrospinning emerging as the primary method of producing nanofibers and related meshes. The current SARS pandemic epidemic and the impending avian flu danger need the highest standards of public health protection. Healthcare personnel usually have a significant risk of infection. Protective devices that can shield the user from potential chemical or biological hazards in the environment are necessary.

Therefore, the development of an extremely sensitive nanocomposite interface is required for the detection and detoxification of chemical agents and biological toxins. Polymer nanofibers are most appropriate for breathable fabric designs since they have shown efficacy in molecular-level sensing. The ideal materials for gas sensing and biosensor applications are conducting nanofibers.

Fabricating functionalized electrospun nanocomposite materials is required to eradicate or destroy these poisons.

Because of their large surface area and the active nano material that is chosen, nanocomposites have a high porosity, which allows chemical and biological agents to be absorbed and broken down into innocuous products. As sensing interfaces, conjugated polymers with certain reactive functional groups may be used.

Using nanotechnology to finish textiles

What is the procedure of sol-gel?

This method creates minuscule particles, ranging from 20 to 40 nm, which are almost unattainable with traditional grinding. Currently, it seems that its primary use is in optical coatings, where the finer particles improve optical clarity. The other prevalent use seems to be the production of fine ceramic fiber.

How is the processing of sol-gel done?

A solvent, often alcohol, is used to dissolve the particle’s liquid precursor. Water is then added, followed by an acid or base. The blend is either poured or coated. The tiny ceramic particles are subsequently formed by the precursor’s breakdown. The mixture gels if the particle concentration is high enough.

To create the appropriate ceramic film or fiber, the gel is dried and then heated to a high temperature.

Shrinkage resulting from solvent and air loss happens throughout the drying and sintering process, and it has to be carefully managed to prevent cracking.

Fabrics that clean themselves

In 1990, Wilhelm Barthlott, a German botanist at the Bonn Institute of Botany, found that the lotus plant, which is highly appreciated for the beauty of its blooms and leaves, has the ability to clean itself due to a high density of minute surface protrusions. Soil deposits are caught by these protrusions, which inhibits them from adhering.

The leaf has a hydrophobic response when it rains. As drops of water tumble about, dust is removed. This self-cleaning feature, which can be replicated for nanotechnological processes on the surface of woven textiles, has the potential to be evolved into a technological advancement. The fabric will be used for certain things, like sails or clothes.

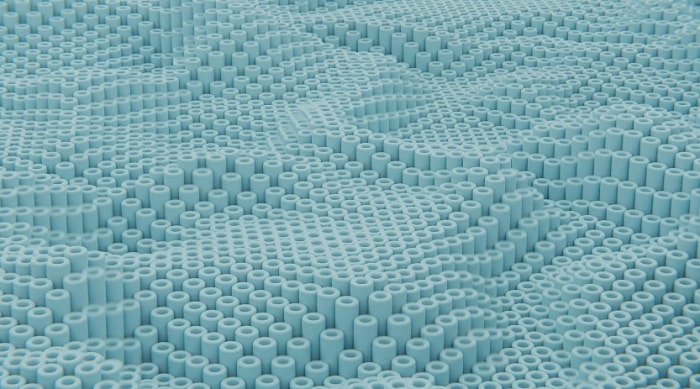

Stain-resistant jeans and khakis have been around since 1990, and an American company called Nanotex created and markets a self-cleaning cotton fabric known as nanocare. The cylindrical structure of the cotton fibers used to make the fabric is altered to generate nanocare textiles. Cotton fibers are similar to tree trunks at the nanoscale. These tree trunks are coated with a fuzz of tiny whiskers made possible by nanotechnology, which surrounds the fiber with an air cushion. Water beading on the whisker tips of the cloth gives it additional buoyancy by compressing the air in the spaces between the hairs. Technically speaking, the cloth has been made very hydrophobic or super-non-wettable.

There are also less points of contact between the whiskers and the dirt. When water is put to filthy fabric, the dirt is transported away with the water as it beads up and rolls off the fabric’s surface because the dirt sticks to the water far better than it does to the textile surface. Thus, the lotus plant’s leaves serve as the inspiration for the idea of soil cleansing.

Antimicrobial coating

It is well knowledge that silver has antibacterial qualities, which stop bacteria and other germs from growing in food or water. Silver’s antibacterial qualities are now acknowledged by science. The antibacterial properties of silver ions are extensive. Using a fiber-reactive polymer such as poly (styrene co-maleic anhydride), silver compounds or nanoparticles may be encapsulated to provide a long-lasting antibacterial finish.

UV-resistant coating

The primary purpose of the clothing is to shield the person from the elements. On the other hand, it shields the user from the sun’s damaging rays. We refer to the rays that fall between 150 and 400 nm in wavelength as UV radiations. A dye, pigment, delustrant, or ultraviolet absorber finish that absorbs UV radiation and prevents it from passing through a fabric and onto the skin improves a fabric’s ability to resist UV rays.

In comparison to organic UV-blockers, metal oxides such as ZnO exhibit greater stability. Because of their larger surface area and strong absorption in the UV, nano ZnO will thus significantly improve the UV-blocking performance. ZnO nanoparticles outperform nano-silver in terms of affordability, whiteness, and UV blocking capabilities when it comes to antibacterial finishing.

UV absorber-treated fabric makes sure that the sun’s harmful UV rays are reflected back, minimizing UVR exposure and shielding the skin from any harm. Depending on the kind of skin a person has and the location, season, and strength of UV radiation, various skin types will need varying levels of skin protection. The Sun Protection Factor, or SPF, is a measure of this protection; the greater the SPF value, the better the UV radiation protection.

Features of clothing with nanofinishing

- Clothing treated with nanotechnology has a water- and beverage-repellent protective covering.

- It is challenging to see through their protective covering with the unaided eye.

- The structure of the treated apparel compresses more when a material is worked at sizes of around 100 nm. Clothing becomes dirt- and stain-resistant as a result.

- saving money and time on laundry.

- This technology incorporates features that are good for the environment.

- While retaining the pleasant touch feel of regular material, nanomaterials improve breathability by reducing moisture absorption and facilitating adequate airflow.

- Clothes stay tidy thanks to the crease-resistant function.

- Products using nanoprocessing are devoid of toxins.

- Compared to typical fabrics, garments remain bright and fresh-looking and are more durable.

- Low manufacturing costs increase the items’ worth.

Applications of nanotechnology in textiles

The uses and scope of nanotechnology in the textile industry are extensive, owing to the progress made in the production of fibers and yarns as well as the creation of fabric finishes.

In summary

Cotton and other textiles have a great deal of promise for using nanotechnology in lucrative ways.

Numerous uses of nanotechnology may be expanded to improve the efficiency of textile production equipment and procedures. Future multidisciplinary research partnerships will provide notable progress in improving the desired properties of textile applications made of cotton and cotton blends.

The world’s largest consumer base is found in the textile sector. Thus, the future uses of nanotechnology should concentrate on improving consumer-focused goods.

Future studies should focus on creating materials with better resistance to stains, shrinkage, and temperature changes, as well as odor-resistant undergarments.